The process involves the installation of simple equipment to convert biodegradable waste generated from our homes into organic manure in a very short time. The first and foremost step towards this process is to separate biodegradable waste from non-biodegradable waste. This aerobic composting system is suitable for independent houses, apartments, complexes, hotels and canteens. This requires very little space in your backyard.

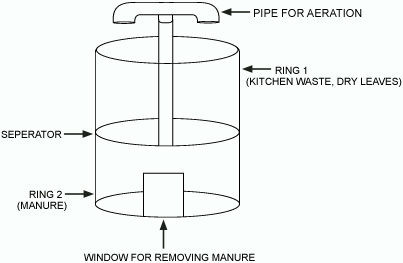

The device consists of 3 concrete rings covered by a non-metallic lid. A poly vinyl chloride pipe is fixed in the center of the lid with perforation below the lid to facilitate air supply. The opening of the lid is covered by a wire mesh for aerobic composting.

A non-corrosive metal ring with a wire mesh is placed above the last ring. Two more rings are placed on this structure. A perforated vertical plastic partition is provided in these two rings to have two compartments for composting more volumes of waste generation and easy mixing. A small window with a sliding shutter is provided at the bottom ring to enable removal of organic manure periodically.

The daily kitchen waste is deposited in the top ring along with dried leaves or shredded paper. This collection is kept moist by sprinkling water. Every 10 days, one or two spoonsful of the process accelerating powder is added to this mixture. Within one month, black organic manure will drop into the bottom ring. This can be removed through the small window periodically. A few drops of lemon grass oil mixed with water can be sprayed to dispel flies and other insects.

Modifications

1. There was plenty of cockroaches entering and hiding in the crevices of the system. . To avoid this , I have sealed by covering it by netted nylon cloth on uneven surfaces between 2nd& 3rd concrete rings of tank. Also I have applied eco-friendly Pesticide inside the tank.

2. The tank is placed on a bed of broken blue- metal and sand about 6 inches thick under earth . This was done for enabling any Earthworms entering into the system for extra assistance. But plenty of Centipedes only entered into the earth. I have cemented the area where the whole tank was placed. Now there is no more Centiipeds inside.

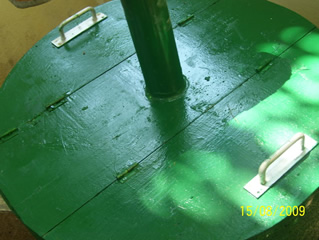

3. To enable easy depositing of kitchen waste& dried leaves / shredded newspaper pieces, I have provided hinges on top of wooden cover, so at the time of depositing, only part of cover need to be lifted slightly, instead of whole cover removal.

4. I have provided 1partition in the the tank divided by nylon netted sheet. This will give you 2 compartments for easy handling.

5. Before, I use a powder, trade name “innoculam” which I buy from Bangalore for accelerating the composting process which I sprinkle about 2 spoonful once in 10 days which is very costly. After experimenting with many substitutes, I found out that we can use cottonseed oil cakes. This can be powdered in any grinding machine.1kg of cotton seed oil cake costs only about 20 rupees. This will last about 1 year.

6.All these modifications were done in the year 2010. for better performance & easy handling.

2nd Modifications October 2011

1.Modification done in October 2011.

2. Provision of plastic coated metal wire mesh with wide gaps, readily available in the market and very cheap, placed between the bottom concrete ring & 2nd ring now ,instead of aluminum ring weaved with copper wire coated with plastic, which is difficult to manufacture & costly..

3.The wooden lid with 2 hinged covers at top is costlier, is replaced by F.R.P. sheet with the pipe inserted at the center, which is cheaper, readily available in the market & lighter. Few small bricks can be placed on top of FRP sheet , to avoid flying away by strong wind..

4.The partition provided in the composting tank is removed now, as whole composting tank will give more space for mixing.

5.All these modifications were done in the year October 2011. for better performance & easy handling.

5.All these modifications were done in the year October 2011. for better performance & easy handling. 3rd Modification in November 2015.

1, From the feed back from the users,3 concrete rings used for the tank were replaced by one plastic drum , which is cheaper and lighter for handling, have very long life. The FRP cover on top, the plastic sieve supporting the 2 inches ventilation pipe at center, window at bottom for taking out organic manure are the same as before.